Error Types

Intro

Welcome to MisprintedLore’s guide to errors found in Disney’s Lorcana Trading Card Game. This is a living resource which will be updated as new errors are found! If you believe there is an error you have that isn’t listed here, please reach via the Contact page.

What is a misprint?

A "misprint” refers to a card with an unintentional printing error. While there are many types of errors, it’s common for collectors or those new to the community to use the colloquial term (used in ordinary or familiar conversation; not formal or literary.), misprints, to describe cards with errors. It’s bound to be that new errors come out as product ramps and Ravensburger begins testing new card types, printing processes, etc, so we’ll continue to update this resource when new ones appear.

Sections

MISCUTS

Off-center vs. Miscut

Miscuts refer to cards which have been improperly cut and are so off that they show another card, sheet edge, or filler. Typically the more miscut, the more desirable.

Off-center refers to cards that are shifted but aren’t off enough to show another card. The more off-center, the more desirable, however they typically don’t command the same premium that miscuts carry. Off-center cards are technically miscut cards, so calling an off-center a miscut is still correct.

Miscut Stitch

Off-center Olaf

Horizontal / Twisted / Vertical

Miscut cards can happen in several ways. The most common way is when a full sheet of cards is fed into the first stage of cutting a bit off, at an angle, etc, and the cards are cut as intended. Depending on how the sheet is fed, the cards can be miscut vertically, horizontally, or even twisted.

While most miscuts show another card, sometimes they can show the edge of the print sheet (white, text or ) or a filler. (see below for more info on fillers)

Horizontal Miscut Enchanted

Twisted Sheet Edge Minnie

Square Corners

When cards are cut, they are first cut from the print sheet and then pass to another machine to die cut the corners. In some cases, the die could be dull, or the cards out of alignment and the corners remain at a 90degree.

While square corners pop up semi-frequently, there is varying rarities of the number of corners which are square corners.

1x square corner - common

2x square corners - uncommon

3x square corners - extremely rare

4x square corners - rare

Extra Material

Square Corner & Factory Tear

Four Square Corners

In rare circumstances cards can have extra material due to either dull cutters/dies or via having production line error (such as folding a corner back).

In instances where a sizeable portion is extra, they are referred to as flag errors as the extra material looks like a flag hanging off of the card.

Extra Material Bottom

Extra Material Bottom

Crimps

Crimps happen during the packaging process and when boosters are sealed. Sometimes cards can shift during packaging and get caught in the crimp of the boost wrapper. The severity of the crimp determines how far into the pack wrapper that it shifts. Sometimes cards can be so dramatically shifted that they are crimped and then cut where the two booster wrappers connect and then cut.

Top/Bottom Crimps

Top Crimp

Top Crimp

Crimp Cut

Crimp Cuts happen when a card is stuck between the packaging of two boosters however the card is shifted enough where it cuts a portion of the card off.

In rare cases, both pieces of the crimp cut can be found, like in the example shown here.

Crimp Cut

Ink Errors

Obstruction

Obstruction errors happen when a print plate is covered in some sort of residue or material which doesn’t allow ink to fully apply to the card stock. This will usually leave a spot void of ink.

Extra Ink

Lorcana cards are printed on CYMK (Cyan, Yellow, Magenta, Key [usually black]) printers. While different printing facilities might have slight variations in saturation of these colors and are within variance, extra of one of the colors or spills of one of these colors can create interesting ink errors.

Hickeys

Print hickeys are small print errors which are caused with a small spec (can even be the size of a speck of dust) of material is on the print plate and causes an anomaly in the printing. Sometimes these can be small white specs (similar to obstruction errors).

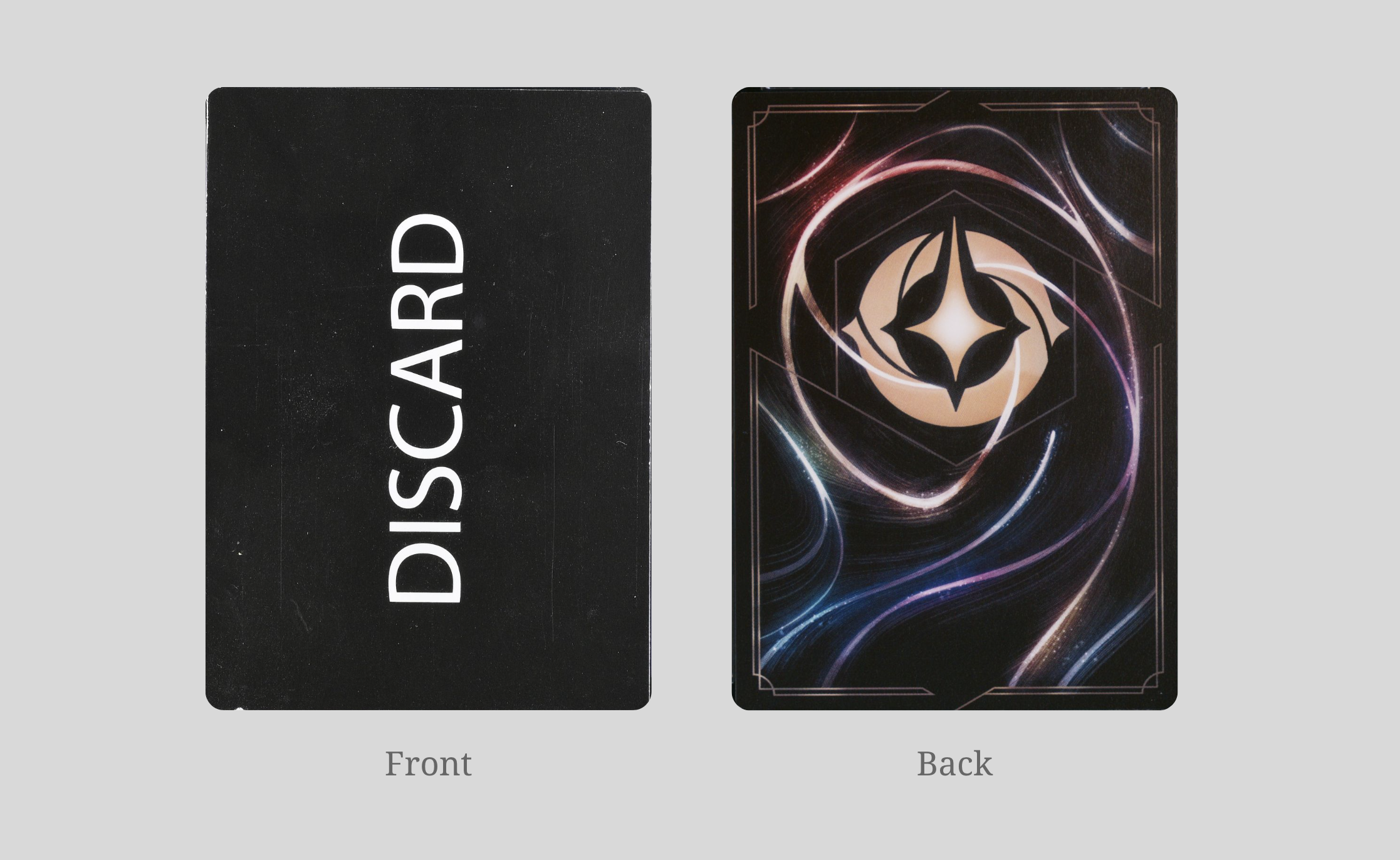

Fillers

Lorcana cards, like other Trading Card Games (TCGs), are printed on large sheets which contain many cards.

When there aren't enough cards to fill the full print sheet, those empty spots become fillers.

Filler cards are meant to be discarded in the factory, though sometimes make it into sealed products and out to consumers.

Fillers aren't misprints as they are printed as intended, however fillers are oddities because, in theory, shouldn't ever have left the factory and not supposed to be released.

Fillers come in all different styles. Different variants can be seen below. Printing facilities are known to re-use filler card layouts so some of the Lorcana fillers may come up in other TCGs such as Magic the Gathering, Star Wars, Pokemon and Yugioh.

What is a Filler?

Please see the Fillers page for more information about the different variants of fillers!

Filler Variants/Versions

Production Errors

Quality Control Markings

During the printing and finishing process, sometimes quality control team members or members of the printing staff may notice anomalies and will mark on the sheets to highlight those errors. These sheets should be pulled out of production, but sometimes these sheets continue through the process and cards wind up in packs.

Legitimacy of these errors - These markings are made when the cards are part of the full print sheet and before any cutting process. If markings from sharpies were done after the cards were cut, the ink from the Sharpie/marker would be seen on the side of the card and would bleed into the cardstock. These QC markings have been seen in Magic the Gathering and Pokemon

Ghost Printing // Dirty Rollers

Sometimes during the print process, print plates can become ‘dirty’ from dried ink on them causing a ghosting effect to happen when they continue to print. In the examples shown you can see that there is a ghosting effect of another card that can be seen next to the cards name.

After cards are cut and continue to be sorted for packaging, sometimes moving through the machines they can become stuck or something can get in the way and cause the card to fold.

The Simba example shows a miscut corner along with a fold.

Folded Cards

Foil and Varnish Errors

This error has only been noticed in cold foiling, due to how the foiling process for those cards is handled. Similar to obstruction errors, residue or some sort of material can be on the applicator when the cold foiling is added to cards. This will cause the foiling to not adhere to the card and be a blank spot on the card. A portion of the card will be foil while the other part will not have it.

Missing Foiling

Unlike Enchanted cards or foils of other TCGs, the cold foiling process happens after the card is printed. Sometimes when sheets are not allowed enough time to cure, the foiling material can remain tacky and stick to the sheet above it when stacked.

This causes the foiling material to be pulled from the face of the card and stick to another card. It’s most noticeable on the backs of cards, however can be seen on the front of cards as well.

Cold Foil Transfers

Foil layers are calibrated to match the different cards on a print sheet. Sometimes the layout of these foil layers mixed up, either by user error when setting the foil layers for sheet or by possibly a last minute change to the sheet layout which causes the foil layer to still reference an old layout.

These types of foiling errors tend to not happen on just one or two cards, but will effect a batch or even just one print facility.

Foil Layer Layout Error

Lucky with a Strength and Willpower frame in the art

Elsa with a foil layer of 3 Lore instead of 2

Incorrect foiling can happen when a sheet is accidentally put through a wrong foiling process which it should receive.

First noticed in Set 9 (Fabled) some commons and uncommons, which only came in non-foil and cold foil versions, were found to have the Rainbow Foiling which was reserved for Epic rarity cards. These cards are noticeable due to their shinier foiling and rainbow of colors which can be seen when tilting the card back and forth.

Incorrect Foiling

Gold foil pressed card names can have extra stamp material, be completely missing or shifted.

While small bits of extra, missing or shifted stamp material are typically common, major shifts, lots of extra material or completely missing names are fairly rare.

Extra/Missing/Shifted Foil Card Names

Powerline World’s Greatest Rockstar with “Powerline” over the cards version

Beast Gracious Prince with “Beast”’s Foiling completely missing.

Starting in set 5, Shimmering Skies, all Legendary cards received a spot varnish layer over the main character of the card. If a print sheet is out of alignment during this varnish process, the varnish won’t line up with the art.

Minor shifts may happen, but when the layer is noticeably off, it can sometimes create a 3D effect on the card.

(Also known as Spot Gloss)

Shifted Spot Varnish Layer

Goliath Clan Leader with missing rarity stamp

Back Errors

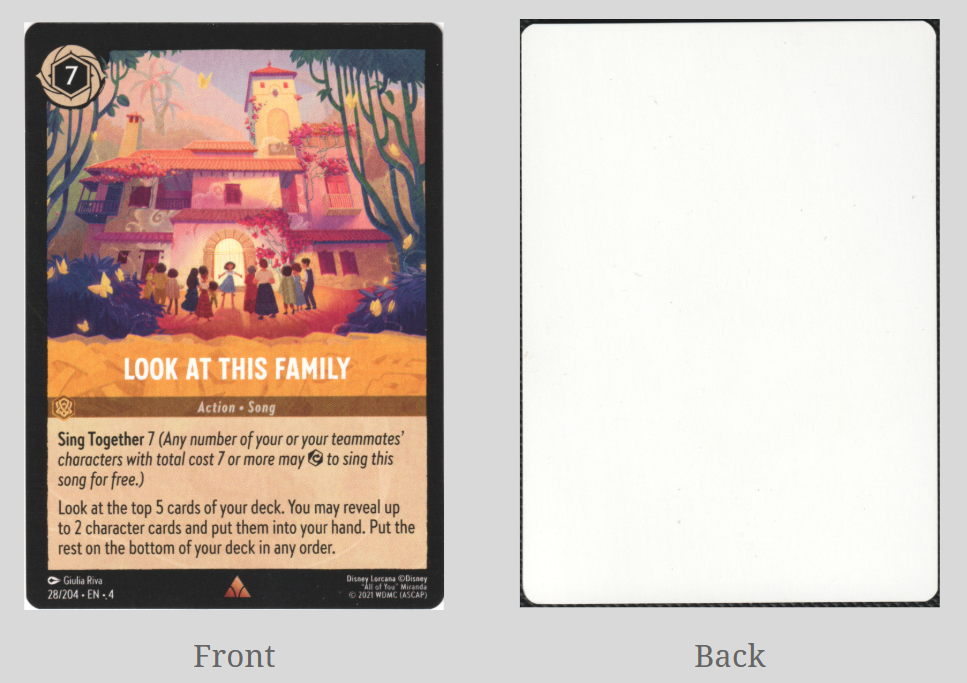

Fronts and backs of cards are printed on different sheets and then glued together to form a sheet that then goes to get cut into individual cards.

In very rare instances, an un-printed back can be mixed into the pile of "good” backs and be applied to printed fronts.

White Back

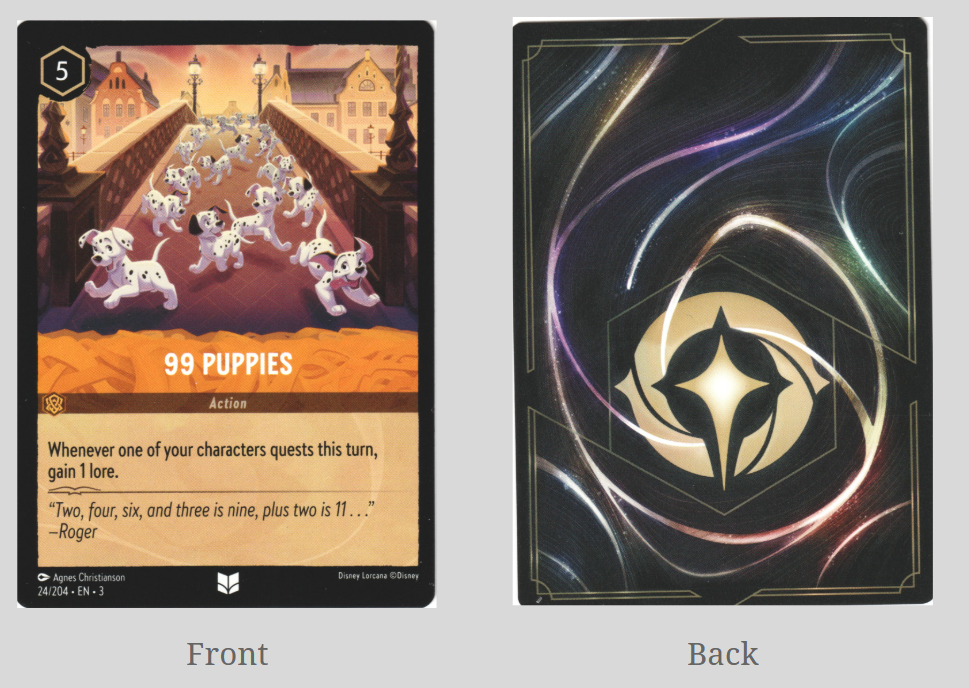

Upside Down Backs

Fronts and backs of cards are printed on different sheets and then glued together to form a sheet that then goes to get cut into individual cards.

In rare instances, the front sheet can be in a different orientation to the back sheet causing the fronts and backs to be in a different orientation.

Misaligned Upside Down Back

Similar to how upside down backs can happen, sheets can be glued together in differing orientations which can cause the backs to be misaligned.

Misaligned backs happen on sheets that happen to have un-equal sheet edge boarders around the card images.

Sheet edges are the blank white space on a print sheet that runs around the border of a print sheet. The top, bottom, left and right sheet edges aren’t always equal which could cause the backs to be off-center as their alignment doesn’t match up.

Correct Back

There is one known sheet to have had a the backs of enchanted cards glued onto the fronts of rare/super rare cards.

Enchanted card backs have a ‘gutter’ which is how we know it’s not the correct back.

What is a ‘gutter’? When cutting cards, a "gutter" refers to the small margin of extra space left between individual cards on a printed sheet, allowing for clean cuts without the risk of the blade catching on the edge of adjacent cards during the cutting process; essentially, it's the space that gets trimmed off to separate each card neatly.

When the enchanted sheet with a gutter is placed on a non-enchanted front sheet, the alignment will be off and the backs will never align.

Different Back

Packaging Errors

Booster pack wrappers are printed in long sheets/rolls. When fed into the machine that packs the cards, sometimes the wrappers can be misaligned. Slight shifts are common, but very off center wrappers are quite rare.

Misaligned Booster Wrappers

Booster pack wrappers are printed in long sheets/rolls. The sheets are usually connected by bright red (sometimes white or black) tape. While this should get picked up during the production process, sometimes boosters make it out to the wild with tape still on the pack where the sheets come together.

Tape Errors

Each (CYMK) color is printed individually and sometimes one color plate is off center causing an almost 3D effect.

Color Layer Registration Error

Accessory Errors

Even official sleeves aren’t immune from factory errors.

Sleeves

Have a type of error that isn’t shown here?

Drop me a line at the Contact page! I’d love to learn more and feature the error here!